Material

Bronze ( CuSn8P ) +

Bronze ( CuSn8Zn3 ) +

PTFE

Introduction

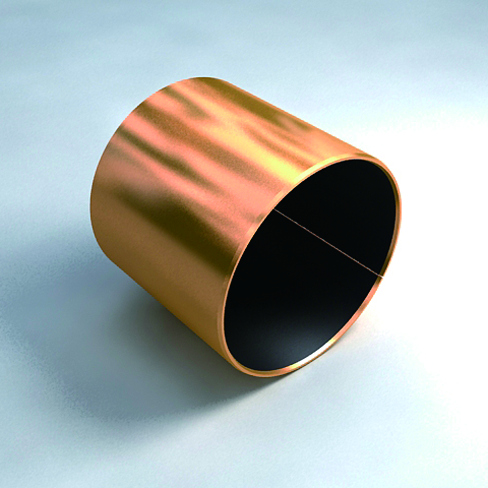

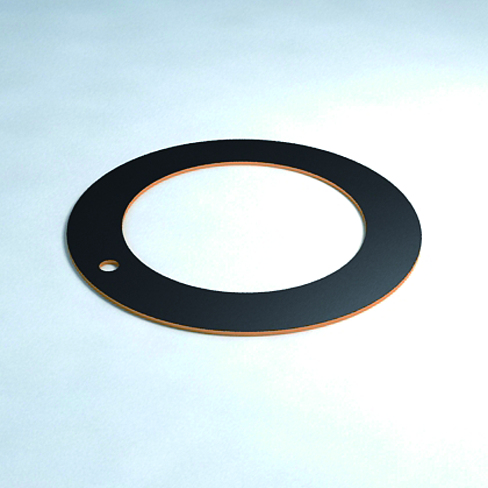

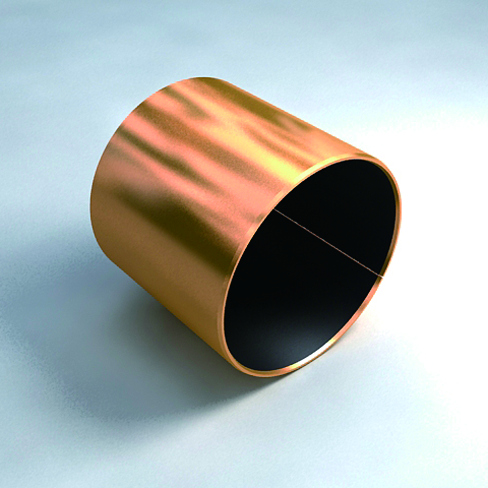

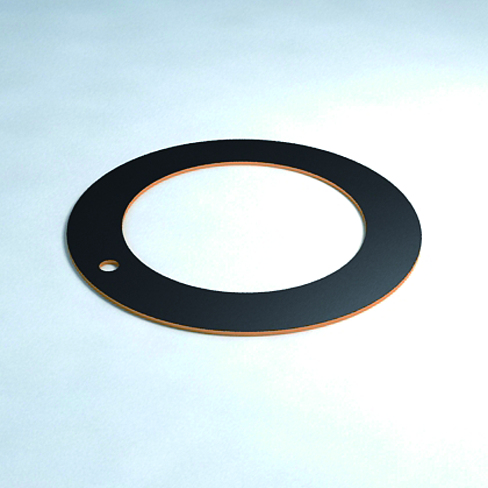

Dry bearings(bronze/black PTFE), made of tin bronze as base material, are produced by the process of being sintered bronze powder as medium layer and coated PTFE as lubrication layer. They are in conformity with the European RoHS environmental protection standards and widely used in the applications of automotive, bicycle, hydraulic transmission, metallurgy and casting due to the advantages of lead free, low friction coefficient, good self-lubricating, good wear resistance and good thermal conductivity.

Usage

|

dry

|

very good

|

|

oil lubricated

|

good

|

|

grease lubricated

|

fair

|

|

water lubricated

|

fair

|

|

process fluid lubricated

|

fair

|

Physical and Mechanical Properties

|

thermal conductivity λ

|

60 W/mK

|

|

max. operating temperature Tmax

|

+280 ℃

|

|

min. operating temperature Tmin

|

-200 ℃

|

|

compressive yield strength δc

|

300 N/mm

|

|

max. static load Psta,max

|

140 N/mm

|

|

max. dynamic load Pdyn,max

|

140 N/mm

|

|

max. sliding speed v-dry

|

2.5 m/s

|

|

max. PV factor-dry, continuous

|

1.8 N/mm2·m/s

|

|

max. PV factor-dry, intermittent

|

3.5 N/mm2·m/s

|

|

coefficient of friction f-dry

|

0.02-0.25

|

|

coefficient of friction f-oil lubricated

|

0.02-0.12

|

|

shaft surface finish Ra-dry

|

0.4±0.1 µm

|

|

shaft hardness

|

hardened/unhardened

|

Previous: IB011 Next: IB013