Products

- IB01 Dry Bearings

- IB02 Marginally Lubricated Bearings

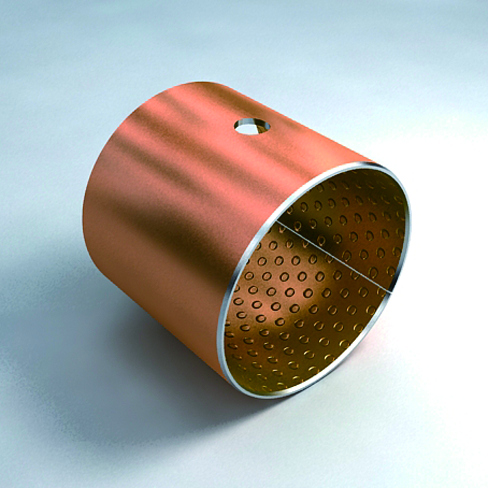

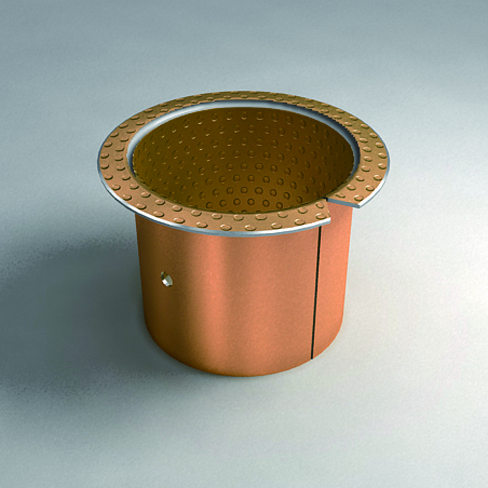

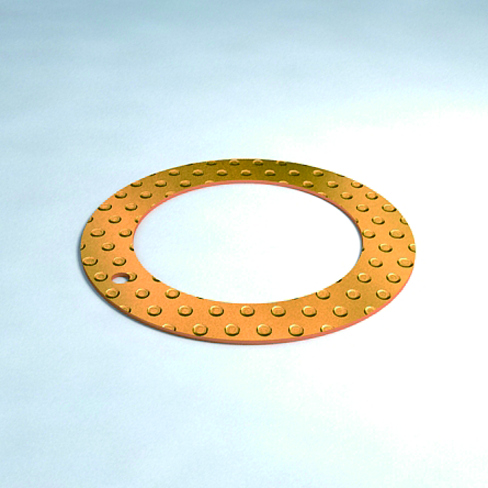

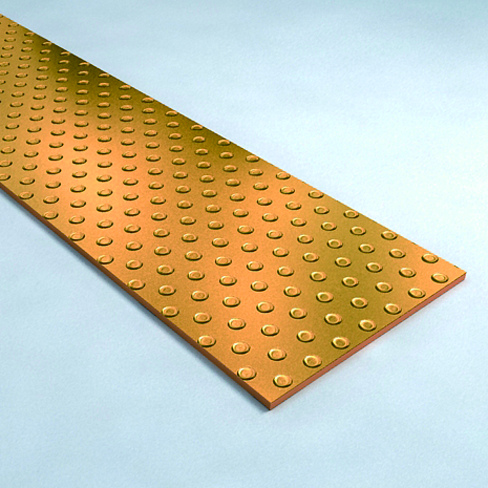

- IB03 Bimetallic Bearings

- IB04 High Precision Roller Guide Bearings

- IB05 Solid Lubricating Bearings

- IB06 Hardened Steel Bearings

- IB07 Self-lubricating Bimetallic Bearings

- IB08 Casting Bronze Bearings

- IB09 Wrapped Bronze Bearings

- IB10 Sintered Bronze / Iron Bearings

- IB11 Linear Bearings

- IB12 Spherical Plain Bearings

- IB13 Engineering Plastic Bearings

- IB14 Door Hinge Bearings

- IB15 PTFE Fibre Fabric Self-lubricating Bearings

IB035

Material

Steel ( DIN-St12|ASTM-A366/A366M-97|JIS-SPCC ) +

Bronze ( DIN-CuPb30|SAE-48|JIS-KJ3 )

Introduction

Bimetallic bearings(CuPb30), made of low carbon steel as base material, are produced by the process of being sintered leaded tin bronze CuPb30 powder as layer. They are widely used in the applications of main shaft and connecting rod of internal combustion engine due to the advantages of good fatigue resistance, good bump resistance and good load capacity.

Usage

|

dry |

poor |

|

oil lubricated |

good |

|

grease lubricated |

very good |

|

water lubricated |

poor |

|

process fluid lubricated |

poor |

Physical and Mechanical Properties

|

max. operating temperature Tmax-greased |

+150 ℃ |

|

max. operating temperature Tmax-oil lubricated |

+250 ℃ |

|

min. operating temperature Tmin |

-50 ℃ |

|

max. load p max |

120 N/mm |

|

tensile strength |

200 N/mm |

|

max. sliding speed v-oil lubricated |

15 m/s |

|

max. PV factor-greased |

2.5 N/mm2·m/s |

|

max. PV factor-oil lubricated |

8.0 N/mm2·m/s |

|

coefficient of friction f |

0.08-0.17 |